Rolls-Royce has expanded its involvement in the aerospace industry in Asia / Pacific, arranged for the production of Trent 1000 engine fan cases in Malaysia. The engine manufacturer has signed a 25-year agreement covering manufacturing, assembly and delivery of packages with UMW M & E, the investment arm of the Malaysian conglomerate UMW, and the newly established subsidiary UMW Aerospace latter.

The agreement is part of the strategy of the company in the UK to create a supply chain closer to customers in developing regions. Three years ago, Rolls-Royce opened a 65,000-square-meters (about 650,000 square feet) of manufacturing leaf fan, assembly and testing plant in Seletar Aerospace Park in Singapore that, in the future, Trent receive 1,000 cases of fan neighboring Malaysia. The agreement follows the development of the Southeast Asian RR as a supply center and "demonstrates the positive impact of the installation Seletar on growth in the ability of the aerospace industry in Malaysia and the rest of the region," according to UMW . The conglomerate sees its expansion in the aerospace sector as an important step that will make it the first Rolls-Royce Tier 1 supplier in Malaysia.

R-R Aerospace President Tony Wood said the establishment of a competitive global supply chain is part of a transformation of the industrial base of the engine manufacturer. "With its commitment to creating a successful aerospace, Malaysia was an ideal country in which manufacturing partners will be sought." As we move closer RR to Southeast Asia, the agreement will reduce labor costs and complement the manufacturing capability in the UK since production is approaching an unprecedented rate, Wood said.

With its first example assembled-Seletar unveiled earlier this year, RR plans to accelerate production Singapore Trent 1000, which competes against General Electric GEnx-1B to power Boeing 787 and the Trent 900, offering for the Airbus. The facility, which accommodates a test engine full size, has an annual capacity of 250 units-a-300, which allows the plant manager UK in Derby, UK focus on increasing production Trent XWB more than 300 units in a year. The engine is the exclusive engine for the new Airbus A350 series

Transfer Trent 1000 making the fan housing for aerospace UMW over the next five years will allow the British factory of R-R in Ansty concentrate on other engines. UMW said the initial agreement expires at the end of 2040, although there is an optional extension of five years.

The move comes as Industrial products Motor Company continue to evolve to meet the needs of more reliable, quieter and more-efficient engines groups. revealing half-year results in early 2015, RR CEO Warren East, said: "In the short term, we are driving a significant transition of mature ones to new and fuel-efficient engines, including the Trent XWB, Trent 7000 [by the planned Airbus A330neo] and Trent 1000. "

The Trent 1000 drove the first flight of the Boeing 787 "Dreamliner" in December 2009 and the first commercial service in October 2011. It was the initial engine certification in both the 787-8 and -9, and was the first engine 787 for 330 cleared for -Minute, extended range twin-engine operations (ETOPS). Now, R-R is keen to see its latest variant energy Trent 1000-TEN (push, efficiency, and New-technology) the first flight of the stretched, short range 787-10.

This new engine has several features developed for more powerful Trent XWB A350, including a "bottom line" and the three-stage compressor blade disc ( "blisk") in front of the high pressure compressor. R-R said that on flights of up to 3,000 miles-ten is expected to offer a specific fuel consumption advantage of about 3 percent, although this difference longer routes disintegrates.

For Flight 787 mid-range, the base 1000 offers a fuel consumption advantage "well above" the GEnx-1B at shorter distances, according to the R-R. An "additional 1 percent" is also said to accrue from higher retention through the life of the engine performance. As been evaluated, one of the 1000-TEN prototypes (engine serial number 11003) was tested in the installation of the US Air Force Aeropropulsion Materiel Command Test Systems (ASTF) in the Arnold Engineering Development Complex (AEDC) at Arnold AFB in Tennessee. Altitude performance was "a little better than the pre-test predictions," said R-R.

Tests Trent 1000-TEN performance, operability, and certification icing cells were performed in engine C-2 ASTF. "The first program [testing] verified the expected improvements in the thrust and fuel efficiency, operability (such as margins locking during rapid acceleration and deceleration), [and] on start," said Tom Schmidt, chief project Aerospace Testing Alliance (ATA), which provides management AEDC information, maintenance, operations and support services. "The icing system C-2 was then installed to run the condition prescribed icing and anti-icing demonstrate the engine and ice shedding characteristics of engine systems."

serial number 11003 is the third test at Trent Arnold 1000: During the first year in 2007, the engine was tested for performance, operation and departure. Last year, engineers tested a 1000 AEDC equipped with performance enhancements Package C. Other tests commercial engine R-R has not participated BR725 and Trent 900 engine for the Gulfstream G650.

Rolls-Royce Trent also has been running "engines maturity" 1000 to ensure the performance of the units equipped with measures to improve performance Package Package B and C and to stay ahead of the operational service units. A recent and new, the customer is Ethiopian Airlines, which has been selected motor (and a package of associated long-term support) to power six Boeing 787-8. The decision is noteworthy because it represents an engine change by the carrier in Africa from the GEnx-1B was chosen to above 13,787. Ethiopian Airlines CEO Tewolde Gebremariam trust RR engines will "deliver excellent fuel burn life, performance and reliability." According to Dominic Horwood, director of customer support for large civil engines manufacturer, RR has "a real momentum in the market," Trent 1000 after being selected by more than 60 percent of motorsport applicable the last five years.

Rolls-Royce Trent 1000 Installed on British Airways Boeing 787-8 Dreamliner

The agreement is part of the strategy of the company in the UK to create a supply chain closer to customers in developing regions. Three years ago, Rolls-Royce opened a 65,000-square-meters (about 650,000 square feet) of manufacturing leaf fan, assembly and testing plant in Seletar Aerospace Park in Singapore that, in the future, Trent receive 1,000 cases of fan neighboring Malaysia. The agreement follows the development of the Southeast Asian RR as a supply center and "demonstrates the positive impact of the installation Seletar on growth in the ability of the aerospace industry in Malaysia and the rest of the region," according to UMW . The conglomerate sees its expansion in the aerospace sector as an important step that will make it the first Rolls-Royce Tier 1 supplier in Malaysia.

R-R Aerospace President Tony Wood said the establishment of a competitive global supply chain is part of a transformation of the industrial base of the engine manufacturer. "With its commitment to creating a successful aerospace, Malaysia was an ideal country in which manufacturing partners will be sought." As we move closer RR to Southeast Asia, the agreement will reduce labor costs and complement the manufacturing capability in the UK since production is approaching an unprecedented rate, Wood said.

With its first example assembled-Seletar unveiled earlier this year, RR plans to accelerate production Singapore Trent 1000, which competes against General Electric GEnx-1B to power Boeing 787 and the Trent 900, offering for the Airbus. The facility, which accommodates a test engine full size, has an annual capacity of 250 units-a-300, which allows the plant manager UK in Derby, UK focus on increasing production Trent XWB more than 300 units in a year. The engine is the exclusive engine for the new Airbus A350 series

Transfer Trent 1000 making the fan housing for aerospace UMW over the next five years will allow the British factory of R-R in Ansty concentrate on other engines. UMW said the initial agreement expires at the end of 2040, although there is an optional extension of five years.

The move comes as Industrial products Motor Company continue to evolve to meet the needs of more reliable, quieter and more-efficient engines groups. revealing half-year results in early 2015, RR CEO Warren East, said: "In the short term, we are driving a significant transition of mature ones to new and fuel-efficient engines, including the Trent XWB, Trent 7000 [by the planned Airbus A330neo] and Trent 1000. "

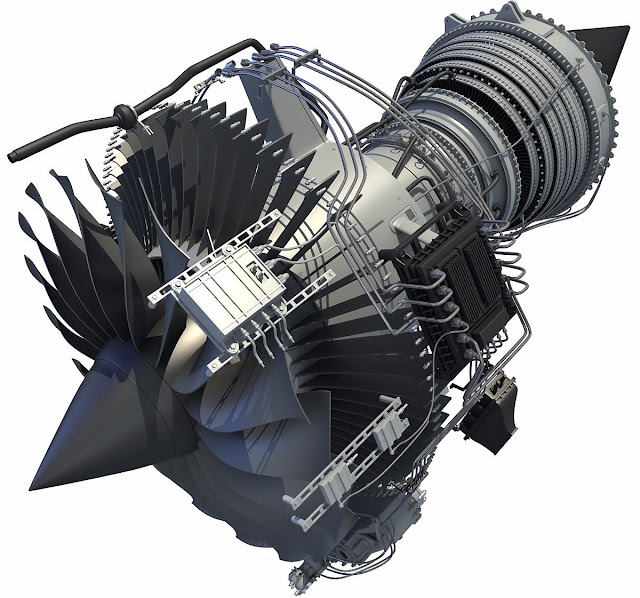

Rolls-Royce Trent 1000

The Trent 1000 drove the first flight of the Boeing 787 "Dreamliner" in December 2009 and the first commercial service in October 2011. It was the initial engine certification in both the 787-8 and -9, and was the first engine 787 for 330 cleared for -Minute, extended range twin-engine operations (ETOPS). Now, R-R is keen to see its latest variant energy Trent 1000-TEN (push, efficiency, and New-technology) the first flight of the stretched, short range 787-10.

This new engine has several features developed for more powerful Trent XWB A350, including a "bottom line" and the three-stage compressor blade disc ( "blisk") in front of the high pressure compressor. R-R said that on flights of up to 3,000 miles-ten is expected to offer a specific fuel consumption advantage of about 3 percent, although this difference longer routes disintegrates.

For Flight 787 mid-range, the base 1000 offers a fuel consumption advantage "well above" the GEnx-1B at shorter distances, according to the R-R. An "additional 1 percent" is also said to accrue from higher retention through the life of the engine performance. As been evaluated, one of the 1000-TEN prototypes (engine serial number 11003) was tested in the installation of the US Air Force Aeropropulsion Materiel Command Test Systems (ASTF) in the Arnold Engineering Development Complex (AEDC) at Arnold AFB in Tennessee. Altitude performance was "a little better than the pre-test predictions," said R-R.

Tests Trent 1000-TEN performance, operability, and certification icing cells were performed in engine C-2 ASTF. "The first program [testing] verified the expected improvements in the thrust and fuel efficiency, operability (such as margins locking during rapid acceleration and deceleration), [and] on start," said Tom Schmidt, chief project Aerospace Testing Alliance (ATA), which provides management AEDC information, maintenance, operations and support services. "The icing system C-2 was then installed to run the condition prescribed icing and anti-icing demonstrate the engine and ice shedding characteristics of engine systems."

serial number 11003 is the third test at Trent Arnold 1000: During the first year in 2007, the engine was tested for performance, operation and departure. Last year, engineers tested a 1000 AEDC equipped with performance enhancements Package C. Other tests commercial engine R-R has not participated BR725 and Trent 900 engine for the Gulfstream G650.

Rolls-Royce Trent also has been running "engines maturity" 1000 to ensure the performance of the units equipped with measures to improve performance Package Package B and C and to stay ahead of the operational service units. A recent and new, the customer is Ethiopian Airlines, which has been selected motor (and a package of associated long-term support) to power six Boeing 787-8. The decision is noteworthy because it represents an engine change by the carrier in Africa from the GEnx-1B was chosen to above 13,787. Ethiopian Airlines CEO Tewolde Gebremariam trust RR engines will "deliver excellent fuel burn life, performance and reliability." According to Dominic Horwood, director of customer support for large civil engines manufacturer, RR has "a real momentum in the market," Trent 1000 after being selected by more than 60 percent of motorsport applicable the last five years.